-

-

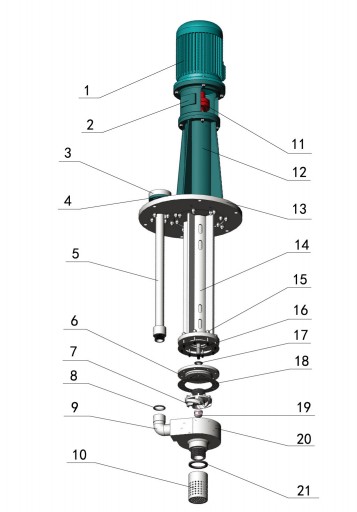

FYUC engineering plastic low-speed cantilever slurry submerged pump

I. General introduction

The FYUC series of engineering plastics low-speed cantilever residue slurry pump is developed on the basis of successful experience and mature technologies of absorbing the development of high speed serial FYUB cantilever liquid FDU pump and low-speed serial horizontal pump.The series of flow components pump adopted the ultra-high mol ecular weight polyethylene (UHMWPE) production, has excellent anti-corrosion, anti-abrasive and anti-impact properties; Meanwhile, the application of axis cantilever structure and the abolition of the lower part of the auxiliary supports, thorough settled the difficulties of the lower part of the auxiliary can not support cooling water and lubrication of non anti-abrasion etc.Due to the low speed, the pump gains better anti-abrasion property and stable operation. Particularly applicable to the corrosive media that contains high volume solidity particles without cooling water. (including the weight of solid particle concentrations ≤ 20% Solid particle diameter less than 1.0mm), the application of the pump ≤ 80 ° C.

Comparing with FYUB cantilever high speed liquid pump, the FYUC series of low-speed cantilever residue slurry pump series is more superior. Owing to its high speed, FYUB series of high-speed cantilever fluid pump sometimes have big vibration, thus the anti-abrasion properties of impeller is also comparatively low. The bearings sometimes gets fever; Moreover, due to its high speed, depth can not be carried out too deep, only one meter below allows. FYUC series of low-speed cantilever residue slurry pump, as its low-speed and small vibration, fair anti-abrasion impeller, therefore the bearing heats quite slight; Moreover, due to its low speed, liquid depths can be carried out deeper, ranging 1.5 meters to 2 meters, which greatly increased the scope of pump application. The pump can be opened in empty.

Comparing with similar stainless steel cantilever pump,FYUC series pump owns light weight, low cost and more extensive anti-corrosive properties, superior anti-abrasion and other advantages that can be widely used in chemical industry, nonferrous metal smelting (gold, silver, copper, lead, zinc, tin, cobalt, tungsten, nickel, etc.), black smelting (steel pickling, Mn-industry), rare metals, and chemical fibers, and pesticides and phosphate compound fertilizer and titanium dioxide, citric acid, Dye, RE, desulfurization plant, a sewage treatment and other industries with large particle transport of acid, alkali and salt and other corrosive media.

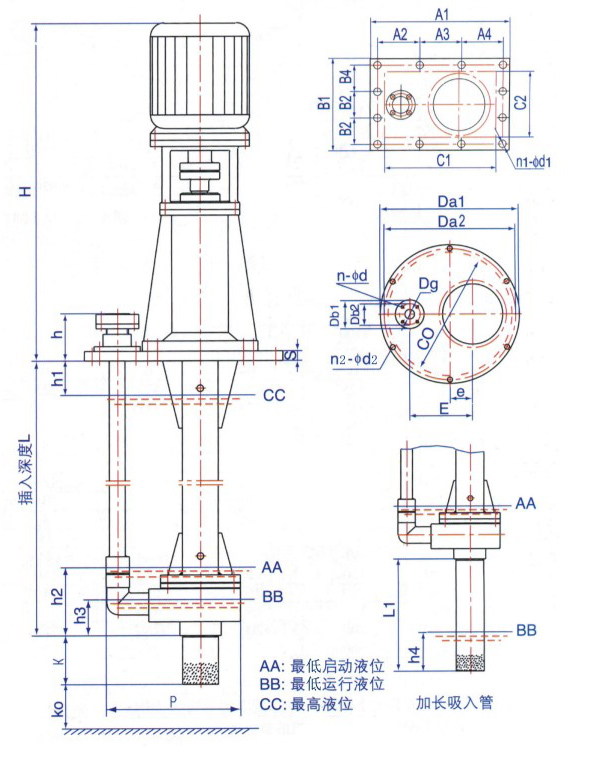

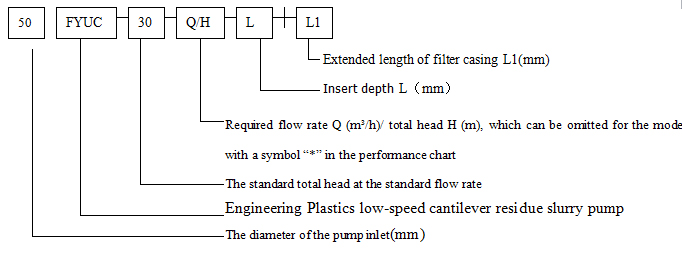

II. Demonstration of model

-

Performance curve Performance parameters Structure description Overall size and mounting size of the pump

-

- Company:

Yixing Linggu Plastic Equipment Co., Ltd. ADD:Yixing porcelain DingShu Zhen Tong Li Industrial Park Road on the 1st Zipcode:214222 Contact:Chen bosheng Tel:+86-510-87409633,87403572,87403345 Fax:+86-510-87426968 E-mail:pump-cbs@pub.wx.jsinfo.net website:http://www.njmhw88.com/ Shopsales:http://yxlgby.1688.com

- Home| About| Product| Honor| Style| Online| Contact| 中文版

Copyright(C)2015,Yixing Linggu Plastic Equipment Co., Ltd.(Yixing Engineering Plastic Equipment Factory) All Rights Reserved. Supported by ChemNet ChinaChemNet Toocle Copyright Notice

.jpg)

.jpg)