-

-

FLU engineering plastic filter pump

I. General introduction

FLU series engineering plastic pressure filtration pump is a kind of single stage, single suck, centrifugal-type high pumping head which is specially designed on the basis of original FUH series engineering plastic pump, which is suitable for pressure filtration working conditions. This equipment possesses the following features:

1. The simple assembled structure of back pump cover, pump body and splint are easily for maintenance. We’ve fully considered the requirements for pressure filtration working conditions involving high medium solid content and wear resistance, the relative partly worn-out components can be relaced and repaired easily, being used more economically.

2. The sealed chamber is of structure of auxiliary impellers. The pressure filtration flow rate is from big to small and its pressure from low to high, so that the pressure inside pump chamber has a big change with high pressure. For the negative pressure effect of auxiliary impellers and blades, the sealed chamber can be kept its basic negative pressure state all the time so as to effectively protect the sealing and make the service life of sealing longer.

3. Ultra high molecular weight polyethylene as the parent material is adopted, with the special medium or under a high-temperature woring conditions, the wear-resistant and corrosion-prevent alloy material can also be used for impellers, if that is 904L, dual-phase stainless steel etc. can be adopted.

4. The back pump chamber easily occurs deposition when the equipment is stopped for using under pressure filtration, especially the status of crystallization, pump chamber is difficult to be purged, therefore, the holes for liquid feeding and discharging are set on the pump body, which can be connected with external valves and pipelines, easy for emptying and cleaning of pump chamber after it is stopped for use.

5. Such series pumps are widely used for pressure filtration working conditions of non-ferrous metal smelting, titanium dioxide, desulfurization etc., especially used in rare and precious metals wet smelting; and due to its high pumping head, the filtration cakes of such series pumps contain small amount of water while its effective compositions using rate is very high.

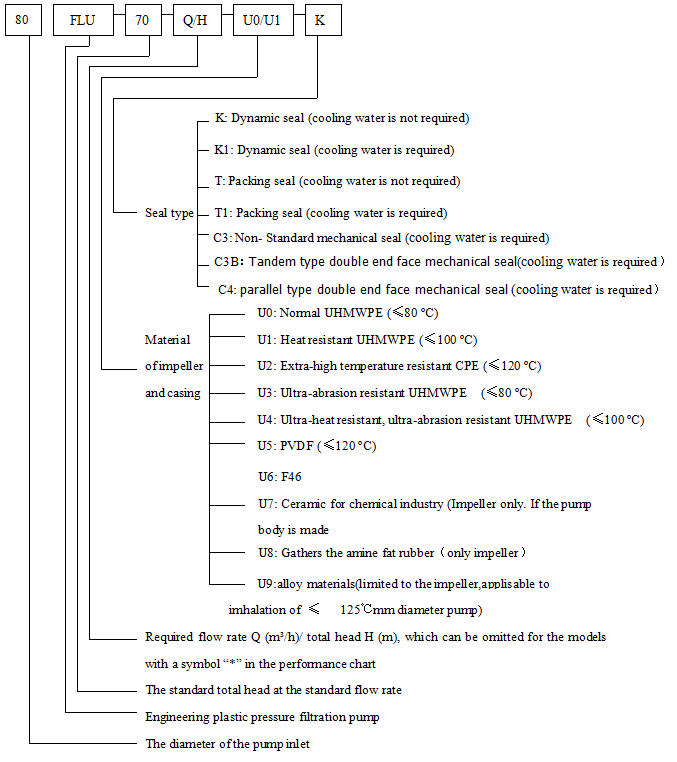

6. Under the pressure filtration working conditions, such pumps must be strictly controlled with a small flow rate; and the state of high pressure duration, if frequency conversion control being adopted, will be more reliable and reasonable.II. Demonstration of model

-

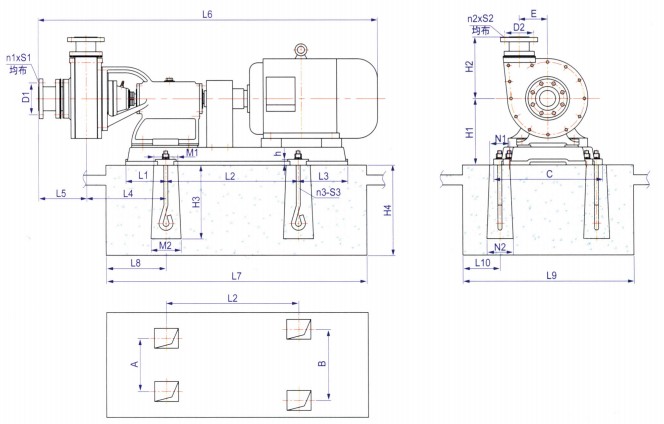

Performance curve Performance parameters Structure description Overall size and mounting size of the pump

-

- Company:

Yixing Linggu Plastic Equipment Co., Ltd. ADD:Yixing porcelain DingShu Zhen Tong Li Industrial Park Road on the 1st Zipcode:214222 Contact:Chen bosheng Tel:+86-510-87409633,87403572,87403345 Fax:+86-510-87426968 E-mail:pump-cbs@pub.wx.jsinfo.net website:http://www.njmhw88.com/ Shopsales:http://yxlgby.1688.com

- Home| About| Product| Honor| Style| Online| Contact| 中文版

Copyright(C)2015,Yixing Linggu Plastic Equipment Co., Ltd.(Yixing Engineering Plastic Equipment Factory) All Rights Reserved. Supported by ChemNet ChinaChemNet Toocle Copyright Notice

構(gòu)說明1(1).jpg)

構(gòu)說明2(2).jpg)

構(gòu)說明3(1).jpg)

構(gòu)說明4.jpg)

構(gòu)說明5.jpg)