-

-

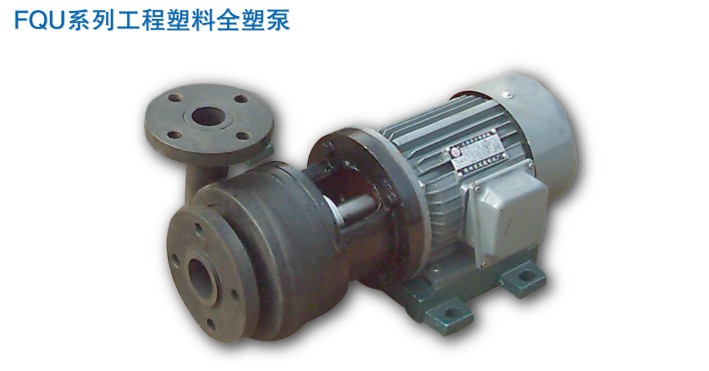

FQU engineering plastic pump

I. General introduction

The FQU series pumps are the corrosive resistant pumps, which are fully made of total engineering plastic. The structure of the pumps is very simple. The main features of the pumps are as below:

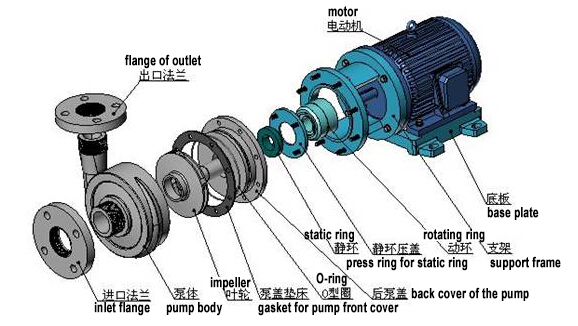

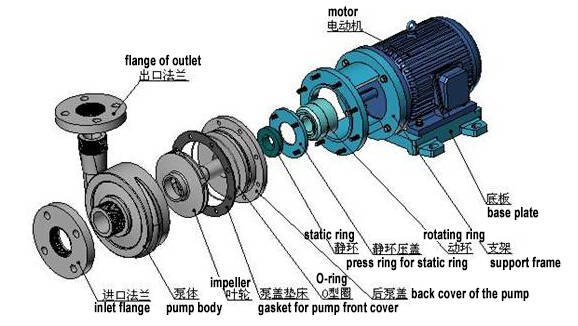

1.The engineering plastic parts of the pump are formed by inject casting. They are light, non-scale with excellent corrosion resistance.

2.The end of the shaft is built in the impeller by casting. The pumped medium won not contact the metal shaft.

3.Equipped with special corrosion resistant mechanical seal. The leakage is greatly limited.

4.High efficiency because of the direct connection structure of the pump.

5.Pump body is supported by a simple metal support.

6.Simple in structure. Easy for assembly, disassembly and maintenance.II. Application

The FQU series pumps are widely used in chemical industry, non-ferrous metal industry (gold, silver, copper, lead, zinc, cobalt and nickel etc.), metallurgical industry (pickling, manganese industry),chemical fiber industry, titanium dioxide industry, rare earth industry, insecticide industry, phosphorous fertilizer industry, citric acid industry, paper industry, desulphation, food industry, water treatment and environment facilities. These pumps are the ideal pumps for pumping clean corrosive liquids. The working temperature of the pump is 80 ºC if material of the pump is FRPP (fiber reinforced polypropylene). The working temperature can be increased to 120 ºC if the material of the pump is PVDF.

The FQU pump can be used in the explosive condition if it is equipped with an explosion resistant motor.

III. Demonstration of model

-

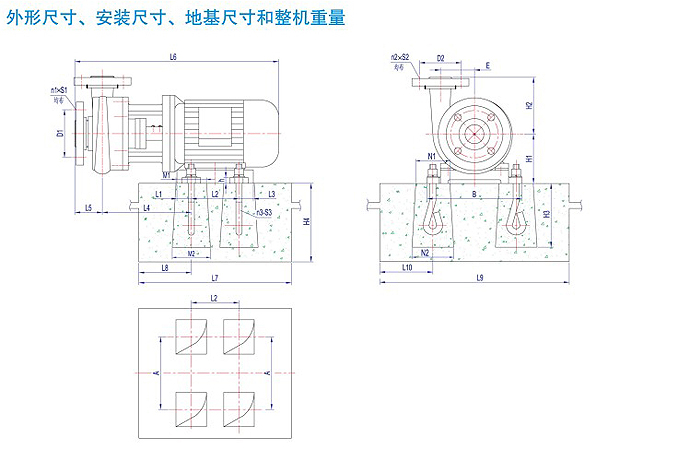

Performance curve Performance parameters Structure description Overall size and mounting size of the pump

-

- Company:

Yixing Linggu Plastic Equipment Co., Ltd. ADD:Yixing porcelain DingShu Zhen Tong Li Industrial Park Road on the 1st Zipcode:214222 Contact:Chen bosheng Tel:+86-510-87409633,87403572,87403345 Fax:+86-510-87426968 E-mail:pump-cbs@pub.wx.jsinfo.net website:http://www.njmhw88.com/ Shopsales:http://yxlgby.1688.com

- Home| About| Product| Honor| Style| Online| Contact| 中文版

Copyright(C)2015,Yixing Linggu Plastic Equipment Co., Ltd.(Yixing Engineering Plastic Equipment Factory) All Rights Reserved. Supported by ChemNet ChinaChemNet Toocle Copyright Notice